Deadpool!

Problem Statement: Create a bot that would win the competition by either immobilizing the other bots or throwing the opponent bot out of the arena

Constraints:

* Dimensions - must fit in a box of 750*750*1000mm. Maximum weight - 60kg (including pneumatic/hydraulic source and batteries)

* No projectiles, EMP shocks or harmful chemicals

* No running compressors.

* Battery and electronics if packaged within the bot needed to be protected from direct hits.

(Here's a link to the official rule list -

https://drive.google.com/open?id=1TOvY297KVxEj5DuiCHWLupAqOXfB-eQL)

Design process:

Between the different types of bots, it was clear that a single extrude drummer bot would have the best chance of winning the competition and it turned out that was the case with the Blanka Botz winning the competition. Their professional approach to the competition along with a larger team and budget aided to their success. The AmpFlo motor that was utilized by their single extrude drummer bot was by itself more expensive than our entire bot. We choose to go with a wedge shaped bot that would be more affordable and have the best chance against a drummer bot. Drummer bots also require three motors which would add to the cost.

Drummer Bot

A wedge bot despite having good defense, without any 'offense mechanism' would be defeated easily. We considered running saw blades but later decided against it due to heavy draw of power and the complicated arrangement to run the setup that could be easily disturbed in case of a violent attack.

This was our initial starting point for our bot. We knew the general dimensions, knew where we would like to place the motors, pneumatic piston, and the connecting point for the lifter.

Here's are some images of our bot under construction.

Working as a weld engineer makes me feel so bad about our welds back in the day. I have definitely learned a lot about how welds should be from then.

Here's a summary of things that we learnt from the project:

1) Connecting batteries in series doubles the voltage while maintaining the same capacity while connecting them in parallel does the inverse. Car batteries have an output of 12V while the capacity is generally around 33Ah. We used two of those batteries in series to power our two motors that were rated at 24V and 350W.

2) Battery output voltage does not remain the same especially depending on the battery chemistry and battery's designed use case. Here's an graph of the output voltage for the lead acid battery that we used.

4) The smaller of the two gears in direct/indirect contact is usually referred to as the 'pinion'. Motor shaft output needs to be reduced through reduction gears. Odd number of gears in direct contact results in same direction rotation.

A lot was learned in regards to chain drives! Firstly, Chain drives cannot tolerate any misalignment, hence the construction needs to be accurate, also due to the nature of the competition, the bot is often under sudden impact (aka shock) which tends to upset the chain drive. If we ever build another bot again, we would definitely go with a belt drive instead. The chain drive should also always have an idler pulley, we learnt this the hard way when one of our motors was disconnected from the wheel due to chain slipping off the sprockets.

5) Always always calculate the coefficient of friction between your wheels and the surface upon which the competition is being held. During our first round, our bot had issue gripping due to the smooth aluminum wheels slipping over concrete surface. I spent the night between the first and second competition by cutting up rubber belts and pasting it onto the wheels using FeviBond(R). The first time I used fevibond, I used it like any other adhesive, mating the rubber and aluminum wheel together as soon as I finished applying the adhesive on both the surfaces. Turns out Fevibond doesn't work that way, you have to let it cure before mating the two surfaces together.

6) BUDGET! Whatever your budget is for the competition and whatever your BOM (bill of materials) estimate for the parts is, you will always need 20-30% more in unforeseen expenses. For us that turned out to be steel plates, drill bits, adhesives and wiring.

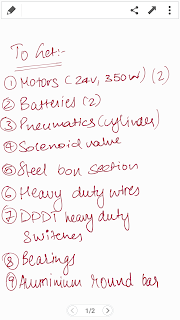

Here's images of lists made during the competition.

Conclusion:

We ended up in the third place in that competition. If we were to go back and do it again with the changes mentioned above, we probably might end up doing better. This competition was a great learning opportunity for me and my teammates, we gained many technical skills as well as learning important communication skills while working as a team.

Here's a CAD screenshot of our design:

This was our initial starting point for our bot. We knew the general dimensions, knew where we would like to place the motors, pneumatic piston, and the connecting point for the lifter.

Here's are some images of our bot under construction.

Working as a weld engineer makes me feel so bad about our welds back in the day. I have definitely learned a lot about how welds should be from then.

Here's a summary of things that we learnt from the project:

1) Connecting batteries in series doubles the voltage while maintaining the same capacity while connecting them in parallel does the inverse. Car batteries have an output of 12V while the capacity is generally around 33Ah. We used two of those batteries in series to power our two motors that were rated at 24V and 350W.

2) Battery output voltage does not remain the same especially depending on the battery chemistry and battery's designed use case. Here's an graph of the output voltage for the lead acid battery that we used.

3) Lead Acid batteries have lower real usage capacity (approx. 50% compared to 80%) and weigh a lot more as compared to Lithium ion batteries. The reason we ended up going with a Lead Acid battery incurring the weight penalty was the easy availability and the lower cost.

4) The smaller of the two gears in direct/indirect contact is usually referred to as the 'pinion'. Motor shaft output needs to be reduced through reduction gears. Odd number of gears in direct contact results in same direction rotation.

A lot was learned in regards to chain drives! Firstly, Chain drives cannot tolerate any misalignment, hence the construction needs to be accurate, also due to the nature of the competition, the bot is often under sudden impact (aka shock) which tends to upset the chain drive. If we ever build another bot again, we would definitely go with a belt drive instead. The chain drive should also always have an idler pulley, we learnt this the hard way when one of our motors was disconnected from the wheel due to chain slipping off the sprockets.

5) Always always calculate the coefficient of friction between your wheels and the surface upon which the competition is being held. During our first round, our bot had issue gripping due to the smooth aluminum wheels slipping over concrete surface. I spent the night between the first and second competition by cutting up rubber belts and pasting it onto the wheels using FeviBond(R). The first time I used fevibond, I used it like any other adhesive, mating the rubber and aluminum wheel together as soon as I finished applying the adhesive on both the surfaces. Turns out Fevibond doesn't work that way, you have to let it cure before mating the two surfaces together.

6) BUDGET! Whatever your budget is for the competition and whatever your BOM (bill of materials) estimate for the parts is, you will always need 20-30% more in unforeseen expenses. For us that turned out to be steel plates, drill bits, adhesives and wiring.

Here's images of lists made during the competition.

Conclusion:

We ended up in the third place in that competition. If we were to go back and do it again with the changes mentioned above, we probably might end up doing better. This competition was a great learning opportunity for me and my teammates, we gained many technical skills as well as learning important communication skills while working as a team.

Comments

Post a Comment